ELIMINATE BOTTLENECKS IN YOUR LOADING DOCK, SLASH OVERTIME AND UNLOCK CAPACITY

Popup blocked? Click here to book

"The automation features that we're using will literally save our company hundreds of labor hours each year"

Max Utilization

Estimate slot lengths and optimize labor and equipment usage.

Cut Down On Overtime

Forecast demand and right-size shifts to flatten peaks.

Better Jobs

Improve morale, retention, and safety with balanced workloads.

Faster Turnarounds

Coordinate dock, yard, and warehouse to cut down dwell time.

Continuous Improvement

Pull reports, spot bottlenecks, and refine processes.

Absorb the Shock

Handle disruptions and seasonal spikes without changing plans.

HOW IT WORKS

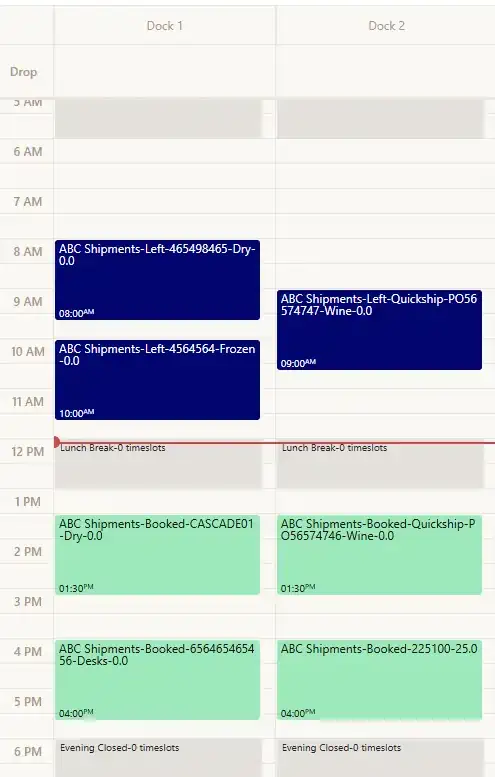

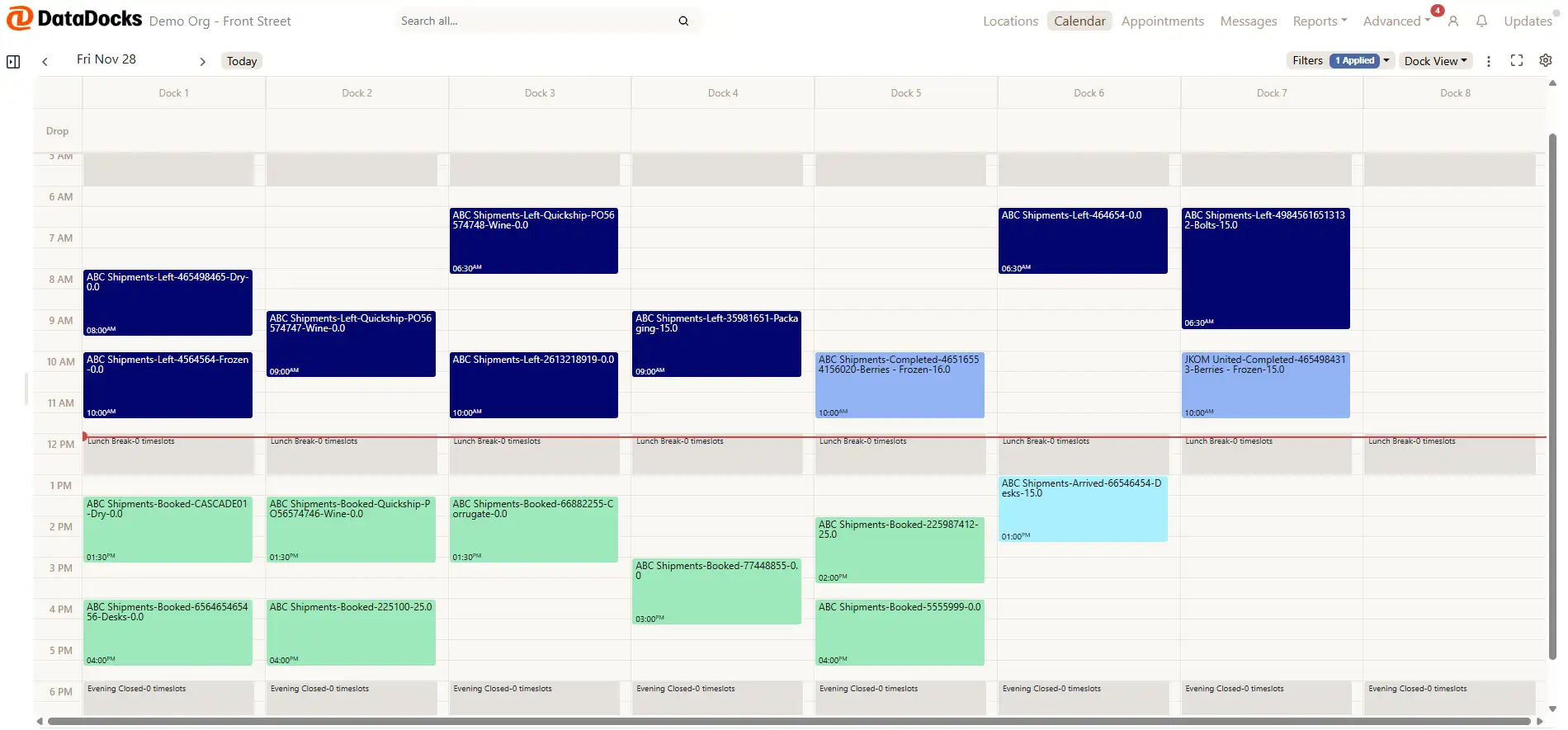

Spread your appointments throughout the day.

Track Durations

Automatically log the average loading and unloading duration for every different load type.

Track Durations

Automatically log the average loading and unloading duration for every different load type.

Refine Labor

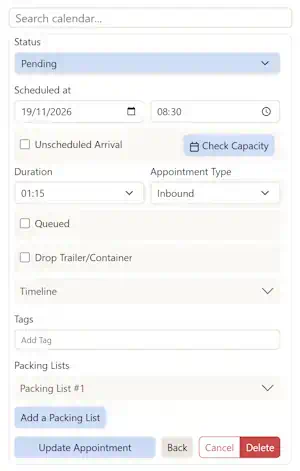

The system learns exactly how much time and labor you need for specific loads, replacing guesswork with data.

Refine Labor

The system learns exactly how much time and labor you need for specific loads, replacing guesswork with data.

Allocate Capacity

Set the right appointment lengths based on actual need, and watch your dock utilization climb.

💡 Strategy:(Use 'Actual Duration' data to justify headcount or equipment budgets.)

Allocate Capacity

Set the right appointment lengths based on actual need, and watch your dock utilization climb.

CLEAR RESULTS FROM OPERATIONS JUST LIKE YOURS

Quality Distribution, LLC

3PL & Warehousing

Challenge: Managing multiple warehouses, each with its own disconnected spreadsheet, meant data silos and operational inconsistency. The team struggled to forecast labor needs accurately or track performance issues, such as carrier no-shows, across the network.

Result: DataDocks centralized scheduling, replacing fragmented processes with a standardized digital workflow. This clarity enabled precise labor planning, real-time visibility into every facility, and the ability to capture and act on critical data like carrier attendance.

Quality Distribution, LLC

3PL & Warehousing

Challenge

Managing multiple warehouses, each with its own disconnected spreadsheet, meant data silos and operational inconsistency. The team struggled to forecast labor needs accurately or track performance issues, such as carrier no-shows, across the network.

Result

DataDocks centralized scheduling, replacing fragmented processes with a standardized digital workflow. This clarity enabled precise labor planning, real-time visibility into every facility, and the ability to capture and act on critical data like carrier attendance.

TNT Express

Delivery Services

Challenge: Manual scheduling was prone to error, particularly when heavy or oversize pallets required more time than standard slots allowed. Without clear visibility into why slots were blocked, these variable loads caused bottlenecks, and the team struggled to align capacity with strict KPIs.

Result: Carriers now request their own slots, while TNT retains final approval. When scheduling conflicts or capacity limits arise, "Kyle" (the AI assistant) instantly diagnoses the bottleneck and suggests available alternatives, allowing the team to resolve capacity issues in seconds rather than hours.

TNT Express

Delivery Services

Challenge

Manual scheduling was prone to error, particularly when heavy or oversize pallets required more time than standard slots allowed. Without clear visibility into why slots were blocked, these variable loads caused bottlenecks, and the team struggled to align capacity with strict KPIs.

Result

Carriers now request their own slots, while TNT retains final approval. When scheduling conflicts or capacity limits arise, "Kyle" (the AI assistant) instantly diagnoses the bottleneck and suggests available alternatives, allowing the team to resolve capacity issues in seconds rather than hours.

Yes! We integrate with:

Don't see your platform listed? We likely support it already. If not, we'll build the integration you need to ensure seamless connectivity with your existing stack.

FREQUENTLY ASKED QUESTIONS

Still have questions? Get in touch with our team

.svg)